Why Robotic Grinding

Industrial Manufacturing Challenge

The world is becoming ever more connected, automated, and intelligent. Everything is a part of a larger system. Processes run at a constantly accelerating speed.

This applies to industrial manufacturing, too. No matter what you make – turbine vanes, airfoils, marine propellers, axles, shafts, or gear wheels, they are all parts of larger systems. Tolerances are tight, and there is no room for slack. Even a microscopic deviation can fail an entire system and stop a process. Thus, your customers expect superior and consistent quality.

The challenge is that competition is intensifying, and your price margins are under constant pressure. You must make high-quality parts more cost-efficiently and faster to satisfy customers – it is hard to maintain healthy profitability.

Manual Surface Finishing is Not Sufficient in Modern Industries

Many manufacturers and processing workshops handle surface finishing such as grinding, deburring, bevelling, and polishing manually. Manual work can reduce quality and consistency, impacting the post-processing stages and entire product life cycle. Poor surface quality can weaken the coating of a part, making it more sensitive to corrosion, wear, and tear, deteriorating its durability and performance. Manual grinding exposes workers to several negative health impacts due to harmful particles, dust, vibration, and loud noise; thus, hiring new employees for the task is difficult.

| According to World Robotics Report, 8% of industrial robotization investments are made to automate arc welding. In comparison, surface finishing is automated only in 1% of cases – although robotization would radically speed up production, increase quality, smoothen the flow, and avoid health risks. |

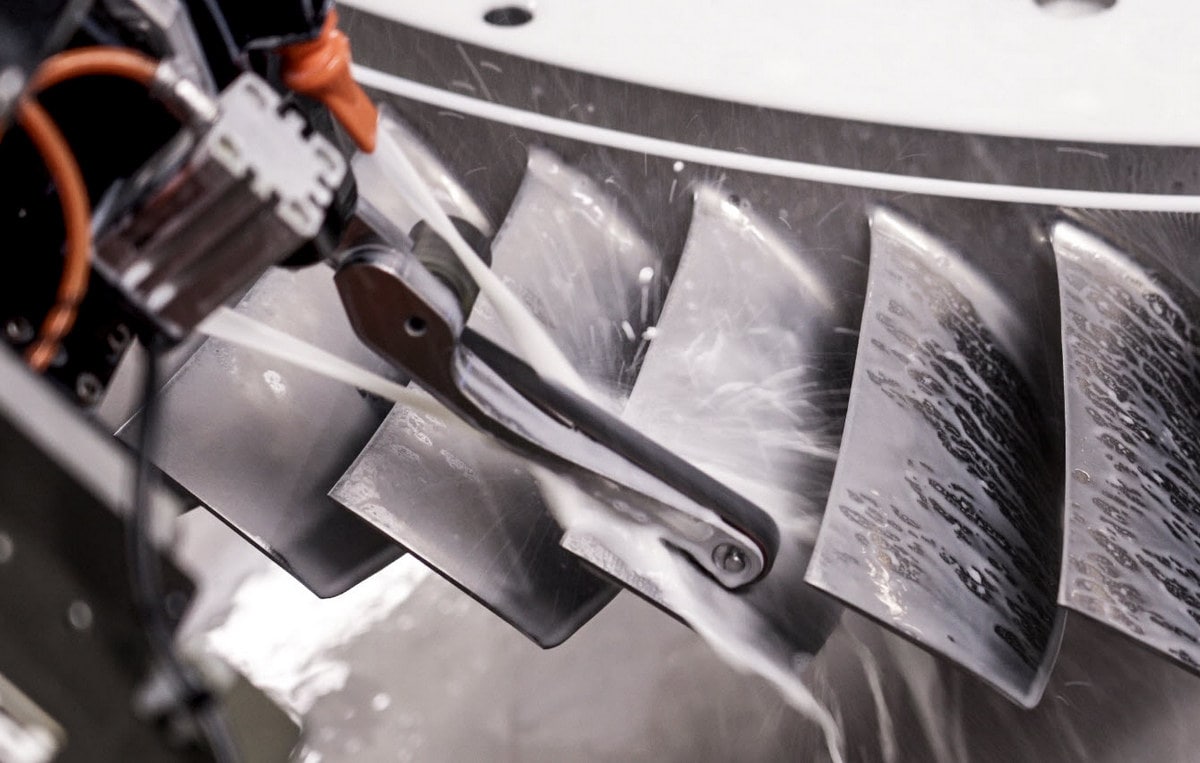

Robotic Surface Grinding

Robotic surface grinding increases the quality and consistency of the processed parts compared to manual work. Better finishing improves the quality of the post-processing stages and overall product quality, durability, and performance throughout the life cycle.

With automation, your entire production process becomes smoother, more predictable, and efficient. You can commit to delivery times and keep customer promises.

Robotized grinding produces uniform quality consistently from one part to another, minimizing scrap and process waste.

Changing manual work to robotic grinding can create a healthier and safer working environment for the workers, increasing employee happiness, working efficiency, and reducing sick leave days.