Trace marking of complex multidimensional parts

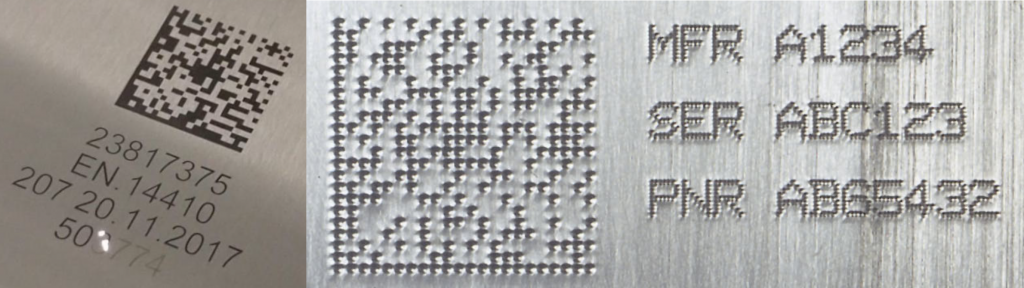

Direct part marking (DPM) is a process of permanently marking work pieces with different product information. DPM is often used by automotive and aerospace manufacturers in order to reliably identify their parts. This allows the tracking of parts through their full life-cycle. Aircraft parts, for example, may be in service for over 30 years and each part has its own manufacturing history, which needs to be individually identified.

There are many ways to uniquely identify work pieces. These include alpha-numeric data, data matrix, QR codes, bar codes, among others.

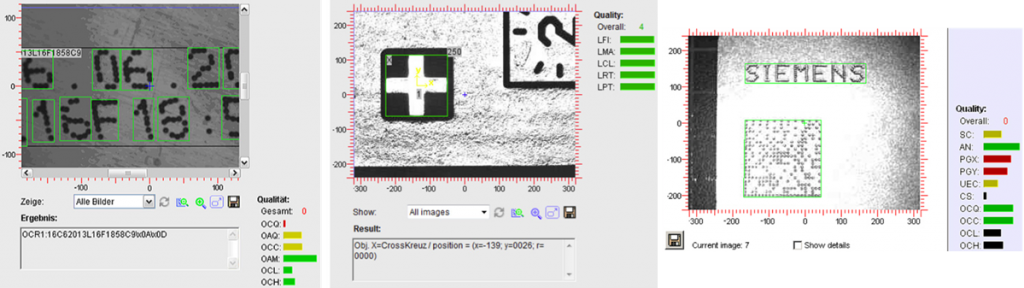

An important part of reliable life-long marking is the capability to verify the results during the marking process. This ensures marking quality and traceability of the part for the following process steps through its life-cycle.

Hybrid marking cell with laser and dot peen marking capability

Hybrid marking cell with laser and dot peen marking capability Verification of marked texts (dimensions & location, OCR & OCV)

Verification of marked texts (dimensions & location, OCR & OCV)