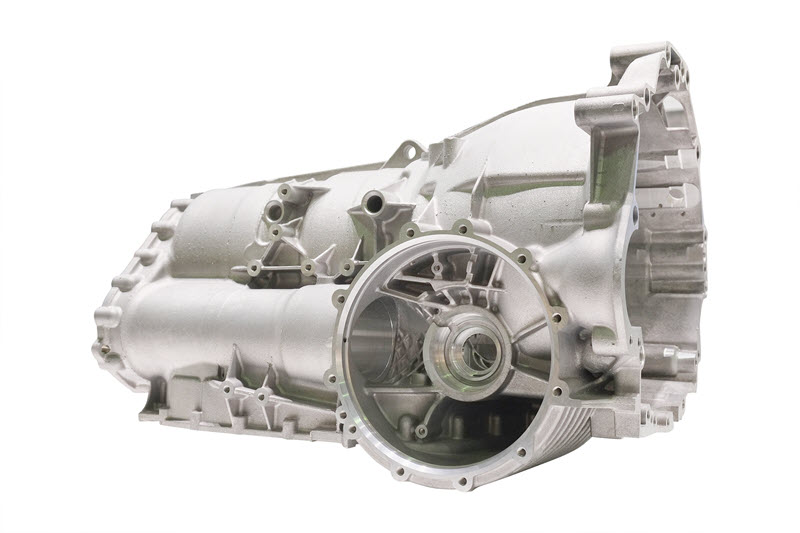

Prismatic component deburring

Flexmill S-series based seven axis robotized deburring solution for the complex prismatic components.

High capacity of tooling with automatic tool exchange systems ensuring easy adaption for most complex components manufacturing.

S-series is ideal solution for aluminum, magnesium and titanium deburring and it designed to comply with NFPA guidelines for combustible dust.