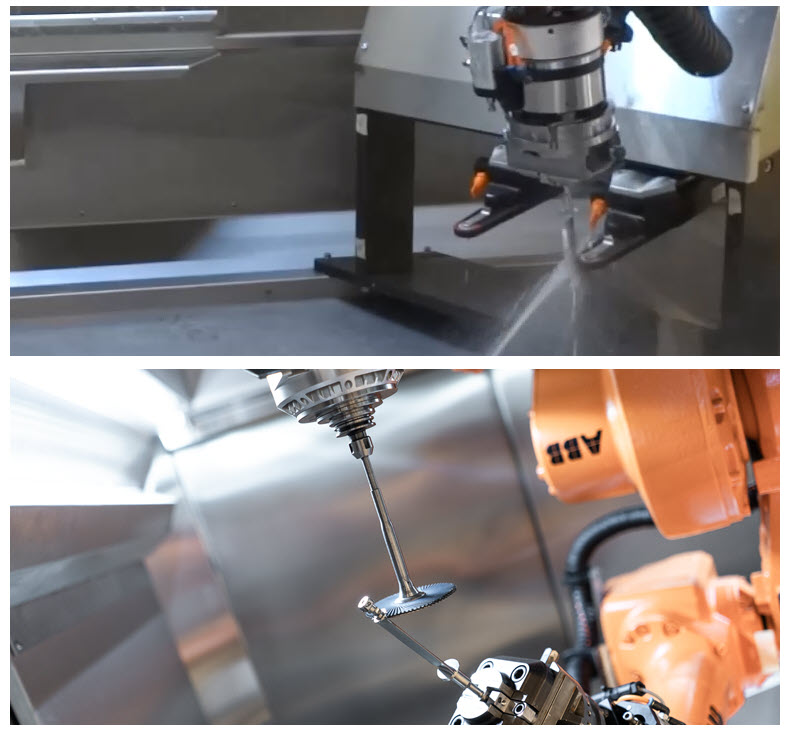

Small machined blade and vane finishing

Small compressor blades and vanes are typically machined to the right profile (to upper tolerance band) and to an approximate Ra 0.8 µm surface roughness.

Flexmill’s solutions can be used for polishing airfoil surfaces, edges, platforms and platform radiuses of parts to a surface roughness or Ra 0.4 µm or less.

Typically, abrasive belts and disks are used for the polishing process. As finished parts are typically manufactured from titanium and nickel-based super-alloys, it is recommended to use a wet polishing process with coolant fluid.. The use of coolant fluid improves the polishing result and the life-time of polishing media can be extended.

Flexmill’s patented fully automatic belt media exchange system improves the autonomy of the system and unmanned production times of up to 24 hours can be achieved (if manufacturing cell is equipped with automatic part loading / unloading).

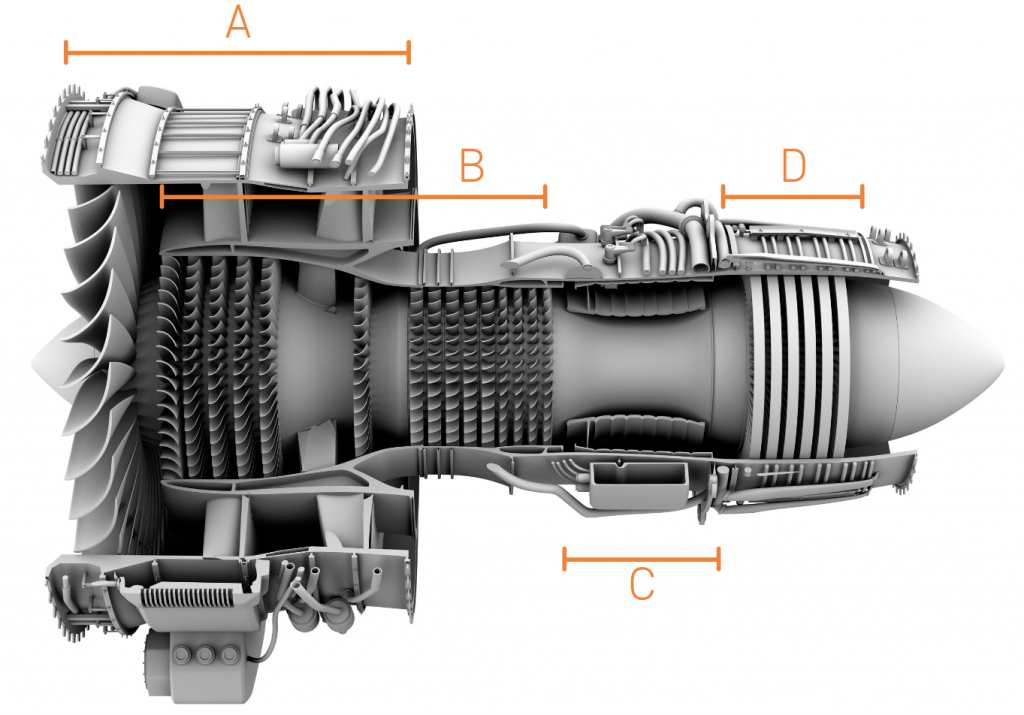

A) Fan section

A) Fan section