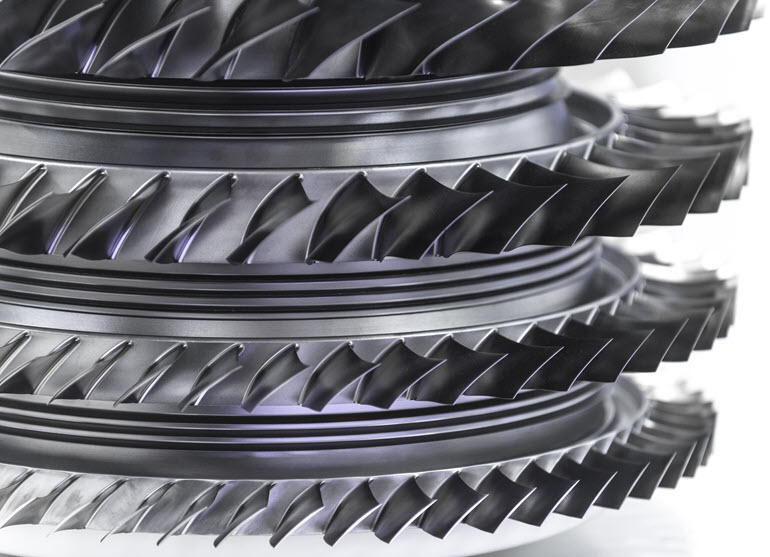

Blisk Polishing

A blisk (bladed disk or integrally bladed rotor IBR) is a turbine component comprising both of rotor disk and blades. It consists of a single part, instead of an assembly of a disk and individual detachable blades.

As the component is very complicated and machining of the work piece takes days, the last surface treatment is very rarely allowed to be completed manually due to inconsistent quality.

Flexmill has developed a solution and the needed process tools to polish the pressure and suction airfoil surfaces of the blisk and to provide long unmanned operation time.