Flexmill’s solution is developed in order to process a demanding high quality surface finish also when the position and surface contour of the work piece is unknown. The Flexmill solution improves quality and consistency of deburred products, shortens production cycles and increases productivity.

The system includes a strong, high payload robot system with a high precision rotary servo table, as well as an micro lubrication or coolant fluid system for work piece lubrication during the finishing process. Typically, the finishing process is completed by utilizing the Electrical Spindle Motor, a variety of angle heads and rotary tools.

Two variations of the system are available depending on the max. dimensions of the work pieces:

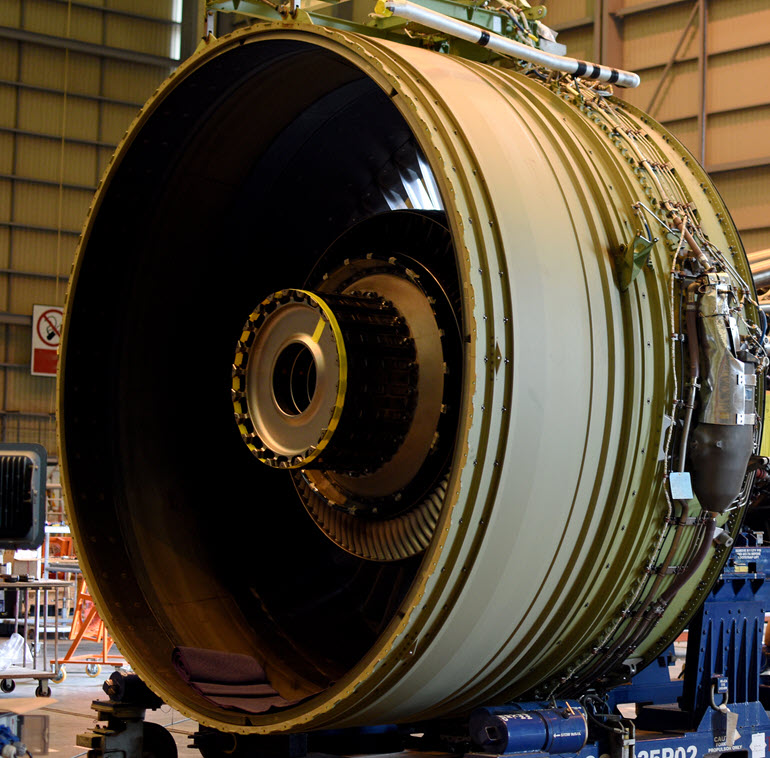

Work piece dimensions: Max D = 2400mm, H=1000mm

Work piece dimensions: Max D = 3500mm, H=1500mm

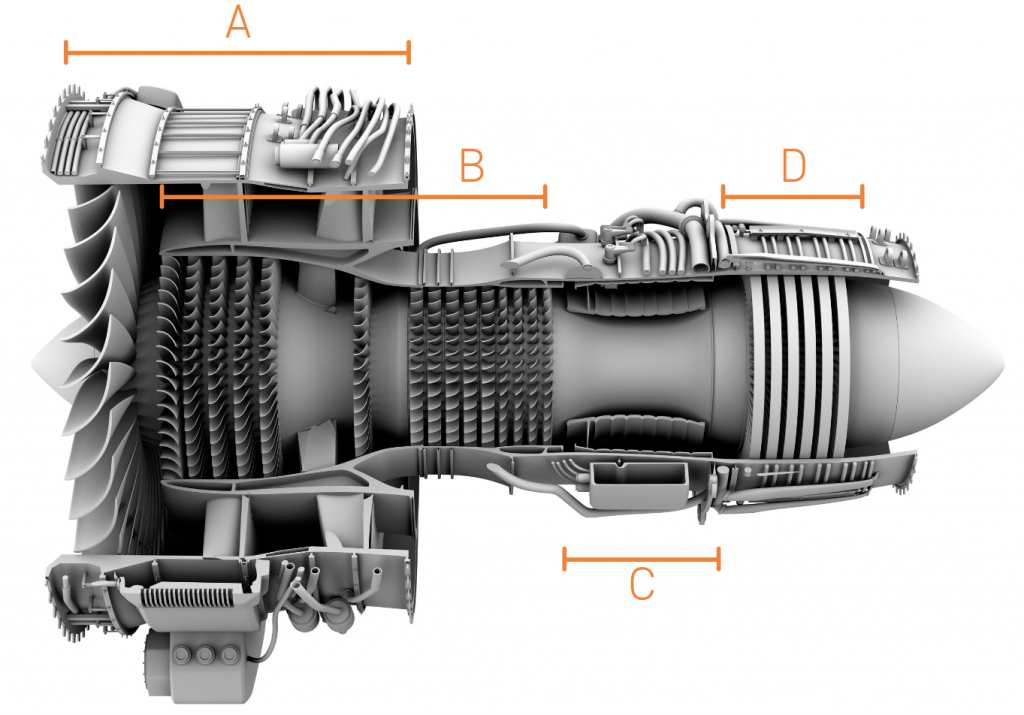

A) Fan section

A) Fan section