Welding Automation without bottlenecks

Robotic welding has been developed to increase precision and efficiency. MIG/MAG welding, wirefeed-speed and arc voltage are just a few of dozens of parameters to be optimized.

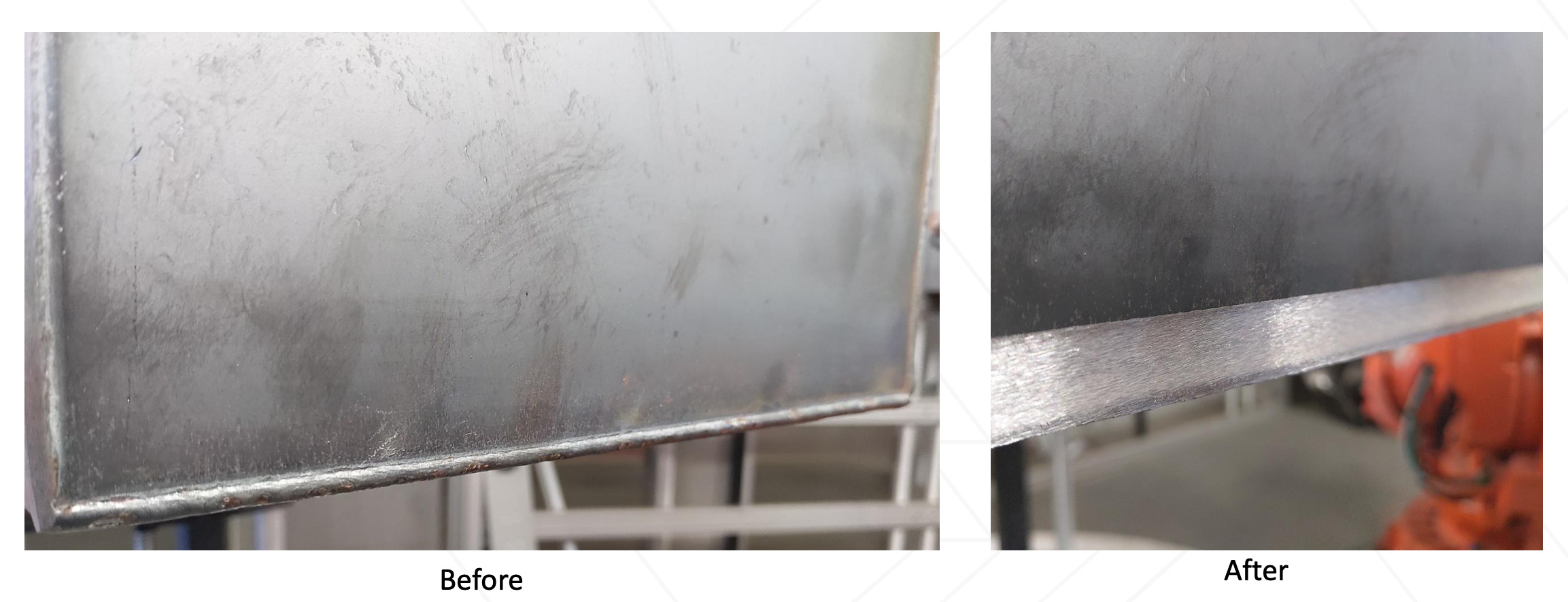

But in order to get 100% out of your welding automation, you need to prepare the parts before welding, and in most welding applications, you also need to finish the surfaces afterwards.

We have been developing robotic surface preparations and finishing for almost a decade, so your grinding capacity will match your welding capacity.

All the benefits of robotised welding can also be achieved in robotised grinding, such as improved safety, better ergonomics for your team, more capacity and lower production costs.

Benefits of automated welt grinding:

- You can use rougher abrasives and operate with higher speeds, thus the material removal rate is higher (more grams per hour).

- The quality is always consistent – your results don’t depend on your team’s grinding skills.

- Robotised grinding allows you to use belt grinders that offer an even distribution of pressure and 3 times longer operation times.

We have prepared a case description with ROI calculation for a robotic welding process with 5 workers in preparation and finishing.

Download the calculation, and don’t hesitate to contact us if you’ve got any further questions.

Case Download - Welding Automation

Fill in your data below in order to download our case description for welding automation without bottlenecks