Gear Deburring

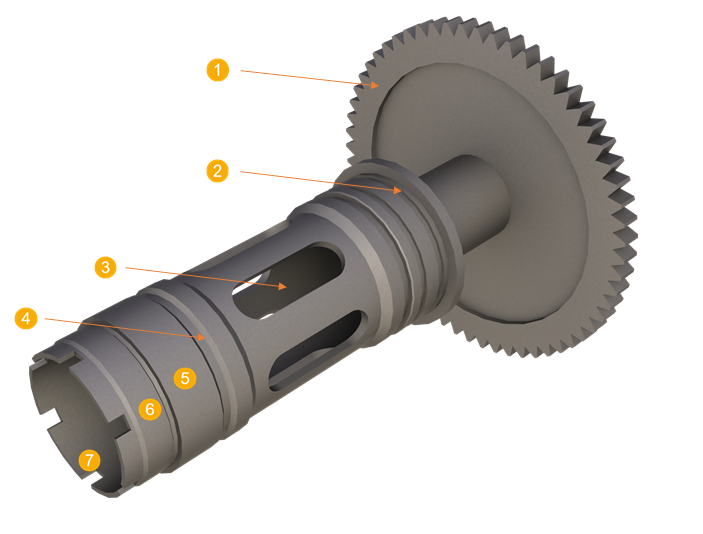

OPTIMIZED SOLUTION FOR EDGE BREAKING OF THE GEAR WHEELS AND AXIS

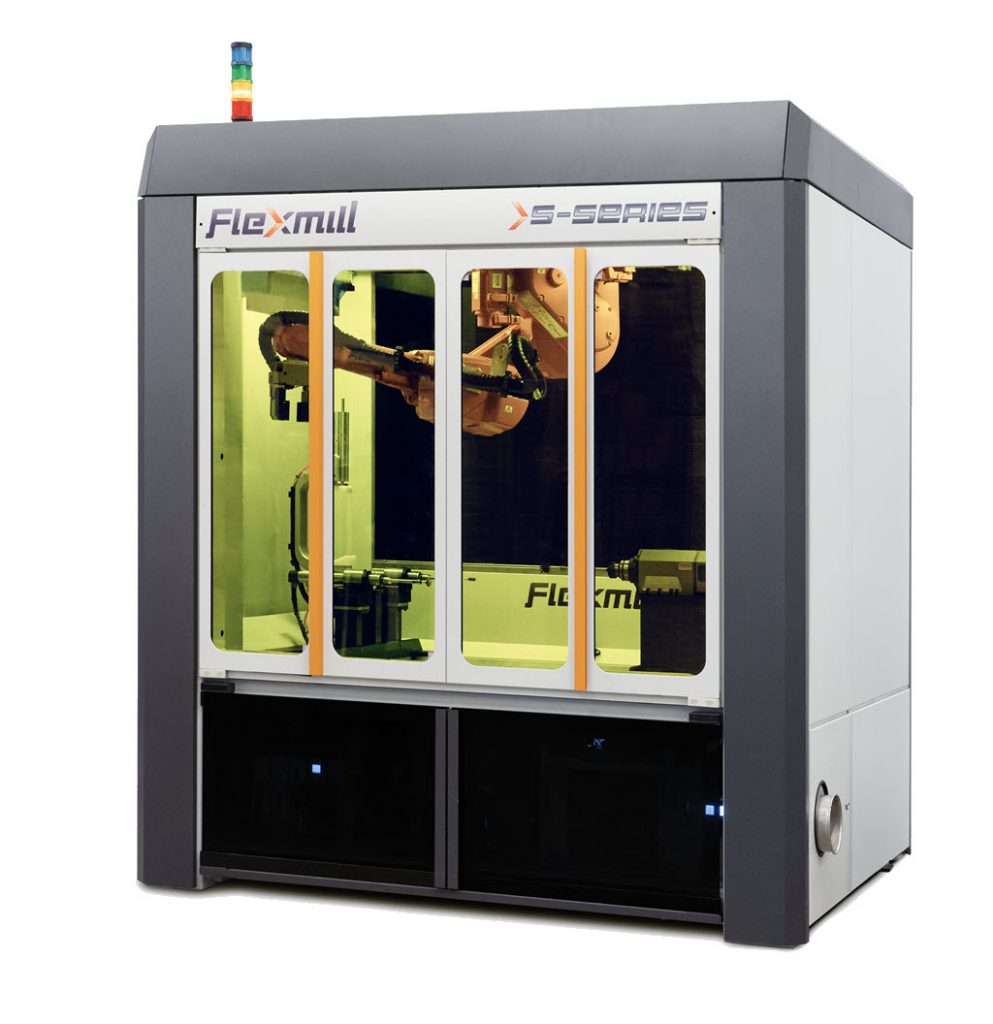

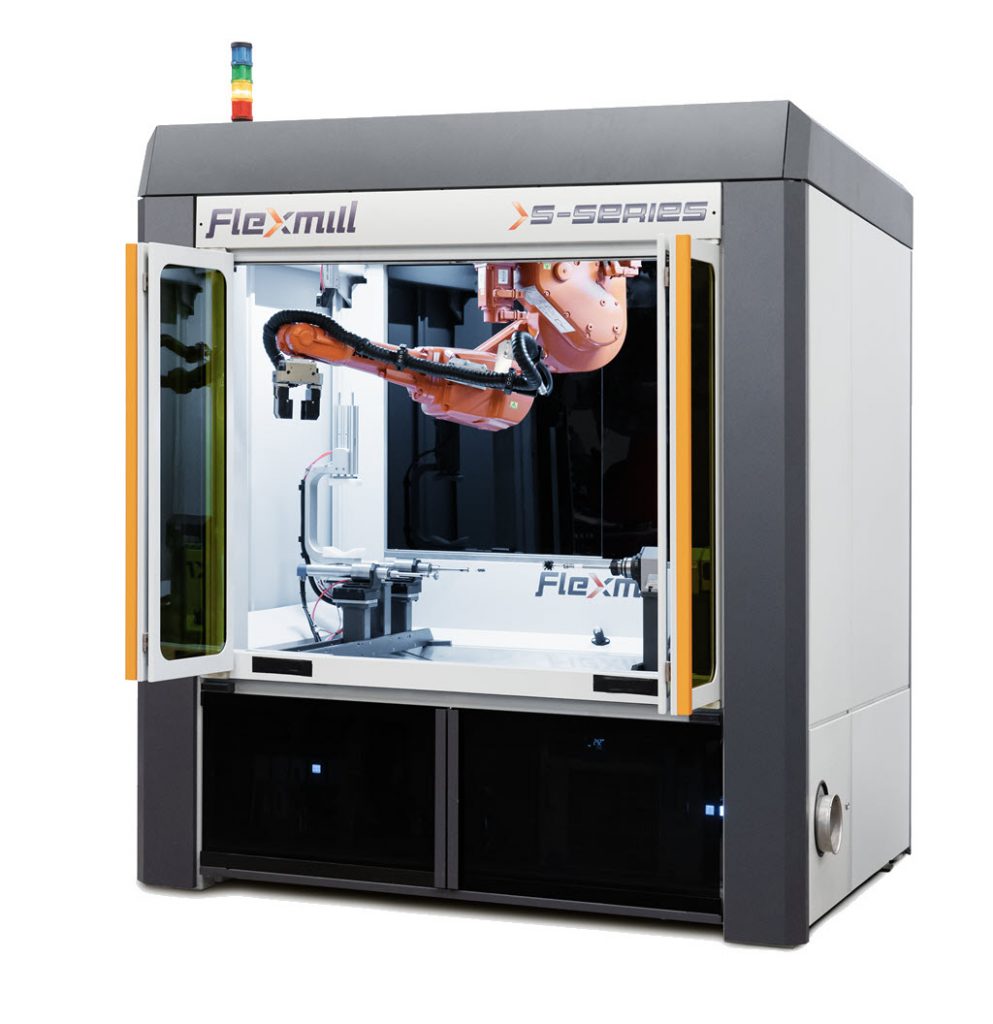

Flexmill’s S-series platform for Gear deburring is developed in order to provide intelligent robotic automation in a manner that provides the best performance and added value to the deburring

and edge breaking process.

S-series platform can be equipped with number of different electrical spindle motors with automatic tool exchange for wide range of rotary tools allowing

extended unmanned production time. Spindle tool stations can be equipped with or without compliance unit.

The tool media storage allows loading and unloading of rotary tools without stopping of finishing process.

Part storage has flexible modular concept that allows different type of workpieces introduction to cell at same time. Each different workpiece holder has a specific insert with RFID tag for automatic part identification. Robot is equipped with modular workpiece gripping system allowing easy adaption of part specific gripper fingers. Workpiece specific gripper fingers are changed automatically according workpiece model.